Herma unveils inline labeling with Bahmüller specialty folder gluer

publié le mercredi 20 novembre 2024

With a specialty folder gluer from Bahmüller, folding boxes made of corrugated cardboard can for the first time be labeled inline on any two sides. This eliminates a complex second process step at the packaging manufacturer and does away with the need for an external provider or manual handling. Here, the unique modularity of the Herma 500 applicator ensures seamless integration and high process reliability – despite the extremely limited installation space.

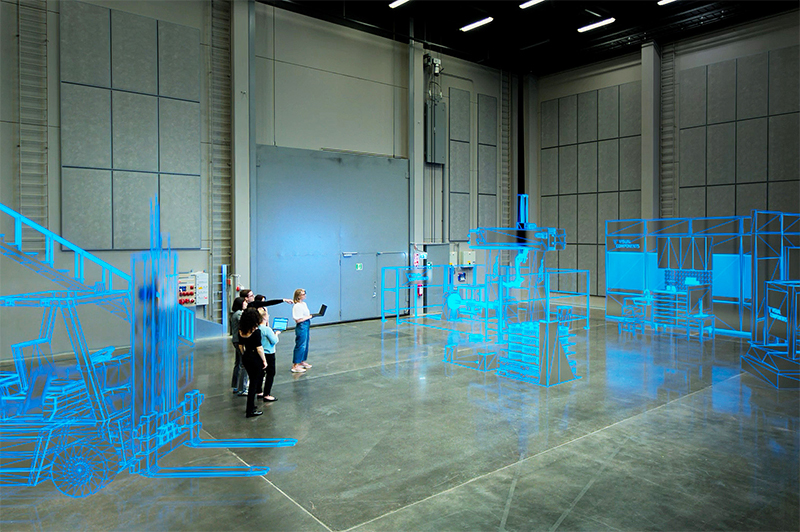

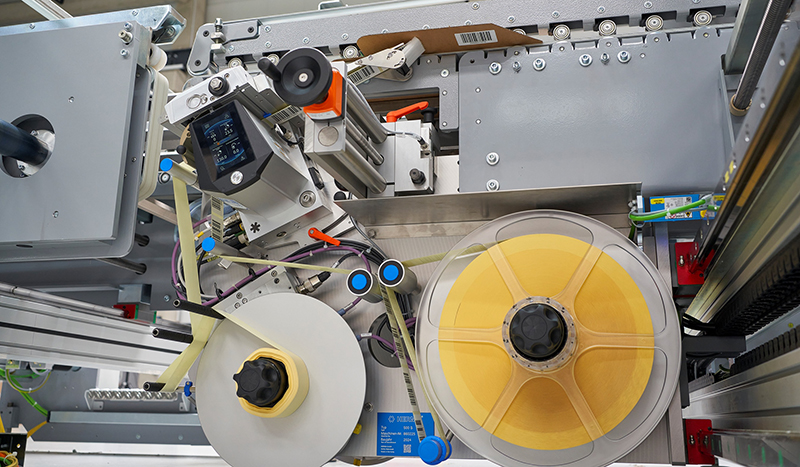

Highly automated and efficient inline processes play a fundamental role if packaging manufacturers and users of finished specialty boxes want their business to grow further. This is why, in cooperation with Herma, Bahmüller – a leading international provider of corrugated board converting systems – has developed a new solution: probably the world’s first series-produced specialty folder gluer which is able to label specialty boxes made of corrugated cardboard inline on any two sides. This is made possible by two high-performance Herma500 applicators, which were seamlessly integrated into a so-called specialty folder gluer of the Turbox type from Bahmüller and are also controlled via the central HMI of the Turbo. To be able to apply labels to two sides, the specialists from the both companies had a trick up their sleeve: The applicators were integrated immediately downstream of the feeder. Two Turbox units with Herma label applicators are already in use at a Bahmüller customer in northern Germany. At present, around 180 Turbox systems are installed worldwide.

« The market is seeing a growth in the demand for labeling solutions for corrugated cardboard boxes, » says Michael Donnert, Senior Sales Manager at Bahmüller. « Batch numbers, use-by dates and security codes are increasingly becoming standard features which users of specialty folding boxes request from their suppliers. » Currently, the unerected cardboard boxes are often still labeled in a second, time-consuming process step on a separate line or by an external provider, sometimes even manually. « By fully integrating the applicator in our Turbox, we are filling a gap in forward-looking inline processes, » continues Donnert. « Users are now offered a complete system from a single source, with Bahmüller as the one-stop provider. With the integration of two Herma500 applicators, we have successfully created a pioneering solution both in terms of design and application technology. »

For specialty cardboard box users, identification using labels is highly coveted because codes on white labels enable high-contrast printing and scanning. For automatic handling of the subsequently filled boxes, the presence of labels on two sides is a significant advantage: With stacking on pallets, this better ensures that at least one label is visible.