ACMA: Automation and sustainability at ProSweets Cologne 2024

posted Wednesday 03 January 2024

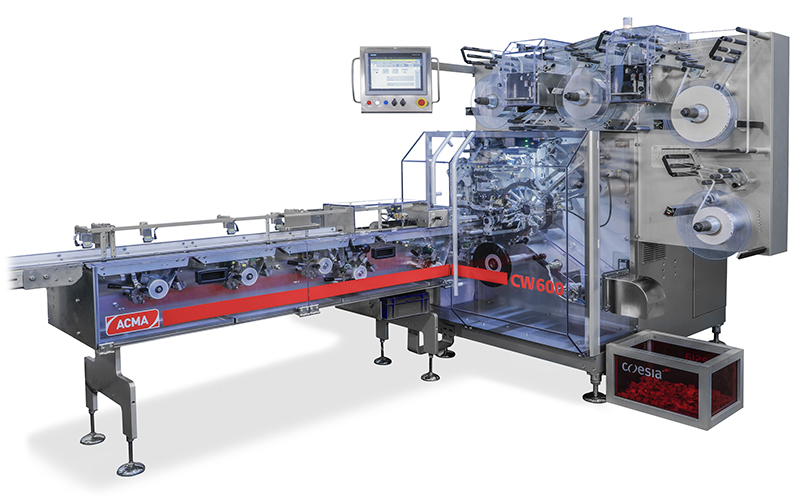

ACMA, a Coesia Group company specialized in packaging solutions for fast-moving consumer goods, will participate at ProSweets 2024 (from January 28th to 31st, 2024), will showcase three technological innovations at the fair: a robotic distribution system, the CW 600 multi-style packer with the new double-protected bow packaging, and Material Gate, a testing unit for paper-based materials.

First, the company has developed three « smart handling » systems for confectionery, designed considering the type of chocolate pralines to be handled, how they need to reach the machine, and the production line’s speed. ProSweets will show a demo of a single-pick up and multi-pick-up robotic distribution system for flat-based products, capable of orienting and arranging chocolates in rows. The system is available in two configurations and is aimed at picking up random products, sorting them and finally feeding them correctly oriented into the machine. It is a modular solution characterized by space-saving design, thanks to features such as the integration of electrical components directly into the machine, eliminating the need for additional electrical cabinets.

Futhermore, the CW 600 is the machine chosen by ACMA to represent the company’s Confectionery portfolio at ProSweets. It is a unit for packaging flat-based chocolates, capable of working with various packaging materials, including monomaterials such as aluminum, PP, PVC, cellophane, and paper. The machine can handle up to eight different packaging formats, addressing market demands for product diversification and making it one of the most versatile platforms in the industry. The model on display in Cologne will be configured to produce the new protected double twist packaging, a particular style of double twist sealed with cold welding. This design has two major advantages: firstly, it better preserves the product’s aroma, and secondly, it protects it from external factors such as water, heat, humidity, dust, and pests.

Material Gate will also be on display – a testing unit born within ACMA’s Sustainability Lab and dedicated to experimenting with new wrapping materials with twist. Material Gate can conduct tests with sustainable wraps, an essential part of developing new packaging materials. Specifically, it can test materials for flat or spherical products with double twist style, verifying machinability and behavior in terms of resistance to mechanical stress. Through Material Gate, ACMA not only collaborates with primary packaging producers in developing new sustainable materials but also precisely identifies adjustments to introduce on customers’ machinery so they can handle the new materials with the same efficiency as the previous ones, ensuring excellent packaging quality.