Cross-sector collaboration launches trial on Holmen’s site in Workington

posted Monday 22 April 2024

A major milestone has been reached in a global innovation project aimed at investigating the feasibility of recycling biogenic CO2 emissions and using it in the manufacturing of household products.

17 organisations, including global manufacturing giants, universities, and innovation experts, are working together in the collaboration Flue2chem to examine the potential for using biogenic carbon emissions as an alternative source of carbon in the manufacture of household products.

The findings from the project will inform the industry and the Government about the feasibility of using non-virgin fossil fuel sources for household and consumer products. The project could, if successful, reduce the need for oil and gas extraction in the future to make detergent and other manufactured goods.

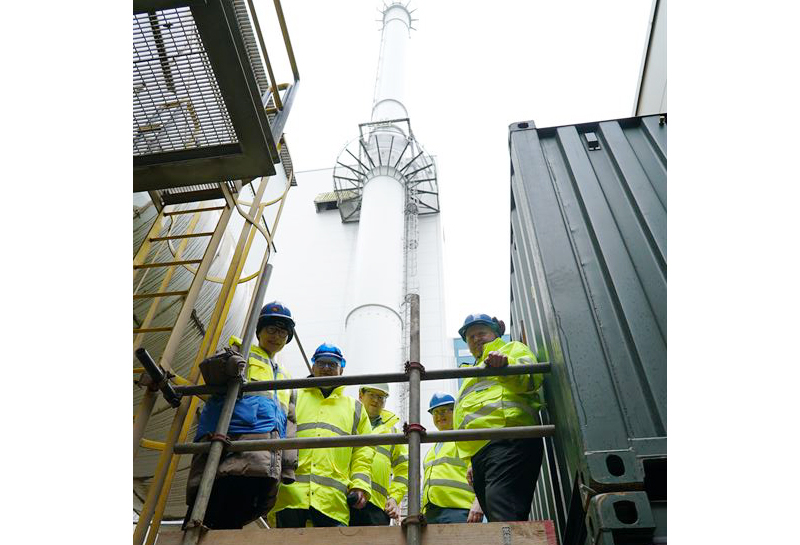

In the project’s first stage, the partners will examine the transformation of biogenic carbon, captured from the flue gas emissions at Holmen’s mill in Workington, into surfactants – the active ingredient in household detergents. After this first stage trial, the carbon capture equipment will be passed to a second site for continued investigation.

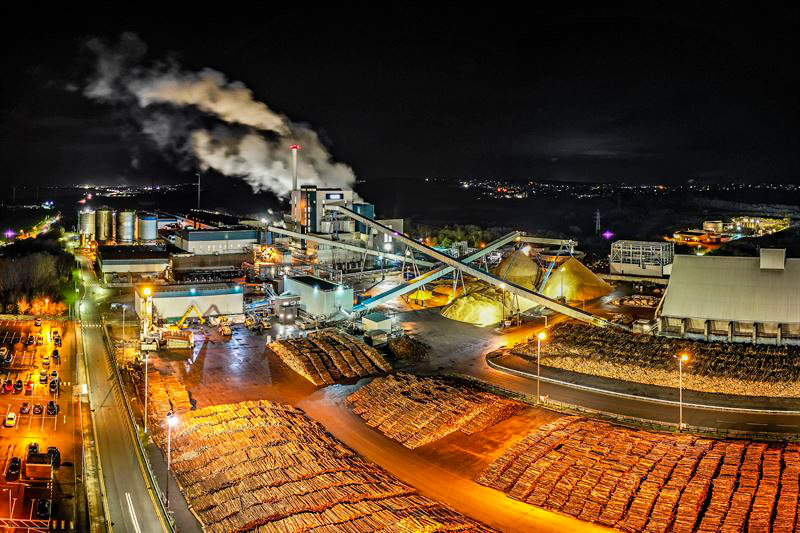

Holmen’s mill in Workington is an integrated pulp and paperboard mill, home to the premium folding boxboard Incada. It operates a biomass-fuelled combined heat and power plant to generate electricity and steam for paperboard production with a surplus of power exported to the national grid.

Earlier this year, the mill took delivery of the carbon capture equipment, which has been developed by the University of Sheffield and CCU International. The plant was commissioned in March and began to capture biogenic carbon for further analysis.