MG2 remote solutions to stay connected

posted Monday 25 May 2020

Covid-19 has changed the rules and the needs. MG2 introduced a series of technological projects useful in managing situations that impose the distance between people, by always focusing on one goal: to be as closer as possible to its partners.

In order to solve the difficulties arising from the existing hindrances to the movement of both people and goods during spring 2020, MG2 has also activated an extraordinary on-site repair service. Thanks to this service, the customers can send the machine parts to Pianoro headquarters where they are repaired and sent back to them.

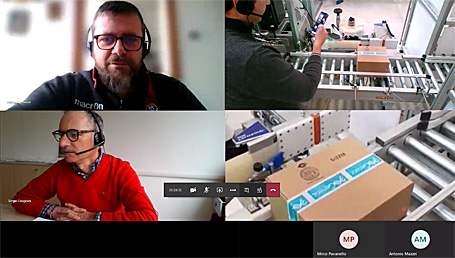

The distance, therefore, does not represent a criticality to organize operational meetings, to test the machines and to run the Factory Acceptance Tests (FAT). MG2 has adopted a wearable technology system based on two video cameras and a smartphone connected to Internet. MG2 technicians wear this system thanks to special harnesses, thus allowing the customers to live a remote user experience as closer as possible to real situation on site.

In such way, MG2 technicians can bring their experience by integrating live video images to machine operating data, which can be shared during the remote meeting. Filming can include fundamental phases such as special parts operation, size change over, management of rejected capsules, real-time information on the sophisticated weight control systems installed on MG2 machines. Images allow the customers to follow the entire intervention, whatever it is: testing, maintenance or repairing.

During Covid-19 emergency, MG2 is fully operational thanks to its constant commitment in searching innovative and sustainable solutions to keep continuous contact with its partners. Indeed, the customers can count both on a consolidated problem-solving support and on important novelties resulting from a constant innovation process which is boosted by this period difficulties. These novelties include the studies on neural networks and artificial intelligence that will be soon applied to MG2 capsule filling machines, aiming at making the machines themselves capable to self-manage maintenance (both preventive and predictive), errors and malfunctions. This self-learning process will be carried out during machine daily operation, according to a logic known as predictive quality.

All rights reserved except agreement written by Emballage Digest or mention of the magazine