The IMA Group will showcase its all-in-one solutions for the pharmaceutical sector

posted Friday 07 June 2024

In an area covering almost 1,400 sqm, the Pharmaceutical Divisions of IMA Group and its specialists will introduce IMA Pharma, the All-In-One supplier specialized in the design and manufacture of innovative machines and complete lines for the processing and packaging of pharmaceutical and nutraceutical products, medical devices assembling, as well as projects concerning digitalisation, sustainability, and customer service solutions.

IMA Active is the ideal partner for each solid dose processing phase: granulation, tableting, capsule filling and banding, weight checking, coating, handling and washing. On show, Aquaria, the new all-in-one solution to wash components and machine parts of different sizes and volumes in completely automatic mode, ensuring greater efficiency and respect for the environment; the Continuous Direct Compression Line (CDC Line), a very lean, efficient and flexible tablet-manufacturing technology that, in combination with PAT, allows easy adoption of a QbD approach, ensuring operation performance and avoiding waste during startup and shutdown.

On show, the integrated line composed by Nenula, the high speed-decontamination tunnel which integrates seamlessly with IMA Life aseptic fill-finish lines, ensuring 100% sterility of RTU material and Injecta 36, advanced robotic fill-finish solution which raises the bar for the high-speed processing of RTU syringes. Introducing an innovative solution for 100% In-Process Control and check-weighting, Injecta 36 is further proof of the key role played by IMA Life in the Ready-To-Use segment for automatic filling & closing machines, able to maximise production performance. Visitors will also discover in world premiere Tile-X, IMA Life’s ground-breaking innovation in the field of fill-finish processing for small batch production. Based on electromagnetic levitation, Tile-X is a compact, Grade A, gloveless modular processing unit for high-value pharmaceuticals such as ATMPs. Also on show, Modula 300, the assembly machine for pre-filled glass syringes capable of performing several operations: plunger rod insertion, labelling, backstop assembly, and a dedicated hub for isolation technology.

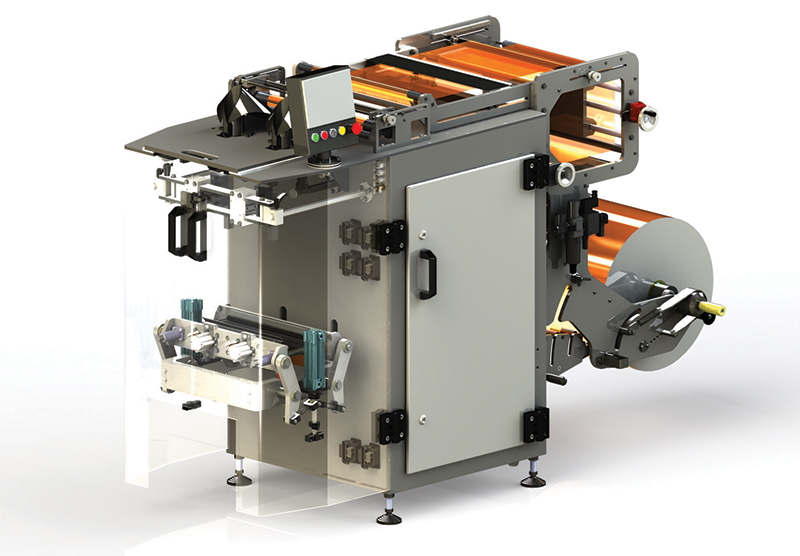

Specialised in primary and secondary packaging, IMA Safe creates blister-packaging machines, capsule and tablet counters, sachet and stick-packaging machines, tube fillers and cartoners. End-of-line solutions, from robotics, handling, overwrapping to case-packing and palletizing are provided by the IMA EOL hub. On show the Giant5-A96 integrated blister and cartoning line, which redefines the parameters in terms of flexibility, speed and compactness; the Red250-A96 deep draw thermoforming and cartoning line, a compact solution for medium-speed production of small batches requiring frequent format changes. Thanks to the robotic handling system, Red250 allows careful and precise manipulation of any type of product, introducing it into the tray with a wide range of possible configurations; the Miniline bottle transport, filling and capping system able to integrate all the functions required to form a complete counting line with a simple and superior footprint: desiccant insertion, tablet or capsule counting, cotton insertion and capping, and can be configured for any product or container requirement and Beta 360 a high-performance vertical sachet packaging machines for 4-seal sachets, able to handle all types of products from paste products to fluid products, powders, free and non-free-flowing products, objects and accessories such as wipes.

The End of Line Hub’s experts will be also present to discuss and highlight the latest solutions available from IMA, completing the line. These include a wide range of options, from bundling and wrapping machines, case packers, palletizers and depalletizers, to state-of-the art, integrated systems featuring robotic solutions for enhanced flexibility and efficiency.