US-based Chase Corporation invests in RMGroup’s bagging and palletizing solution

posted Monday 12 February 2024

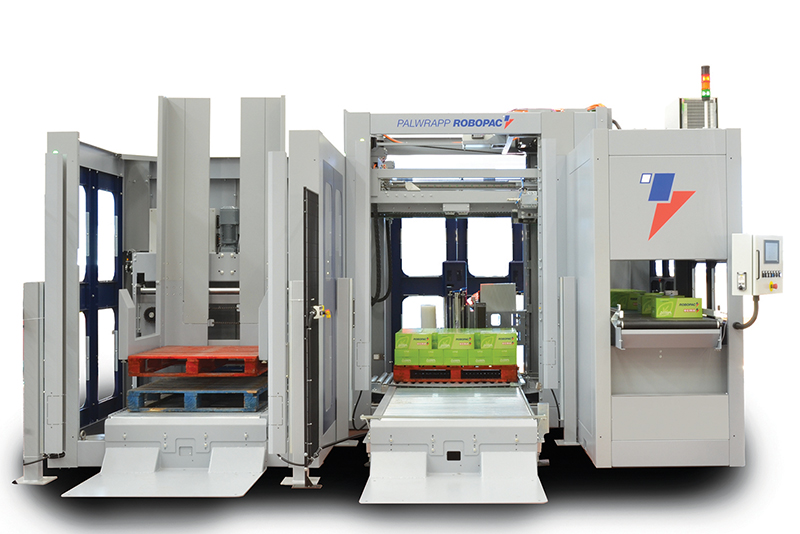

Leading robotics and automation company, RMGroup, has recently installed a FPK-26 form, fill and seal bagging and palletizing solution to enhance packaging efficiency and safety at leading superabsorbent polymer (SAP) manufacturer, US-based Chase Corporation. The investment was influenced by RMGroup’s unparalleled expertise in the automated bagging of de-aerated dusty products, a characteristic of the materials processed by Chase Corporation.

The system was selected to improve operational metrics and resolve issues with the company’s existing manual process. Being a key feature, the palletizing robot has since been instrumental in ensuring operator safety by eliminating the need for manual handling of heavy 55-pound bags. Additionally, the machine’s precision in-filling has significantly enhanced product quality, ensuring customers receive accurate quantities without excess giveaway. This precision has also led to a reduction in overall packaging costs by allowing the use of more cost-effective materials at a faster rate.

The automated bag line, a replacement for the company’s old manual filling stations, has not only accelerated the packaging process, thereby enabling quicker order turnaround, but also met and exceeded operational expectations within a few months of its installation.

RMGroup is a leading manufacturer of a wide range of manual and automated packaging systems, including: ABB palletising and flexpicker systems, mobile packaging lines, bulk filling and material handling systems, as well as supplying high speed form fill and seal packaging lines and AGV’s. Based in Newton, Powys, the company’s target markets include food and beverages, horticulture and garden, aggregates, chemicals and minerals, wood and timber, agricultural and crop.