Ineos and Coveris announced new application for Recycl-IN polymer grade range

publié le lundi 14 février 2022

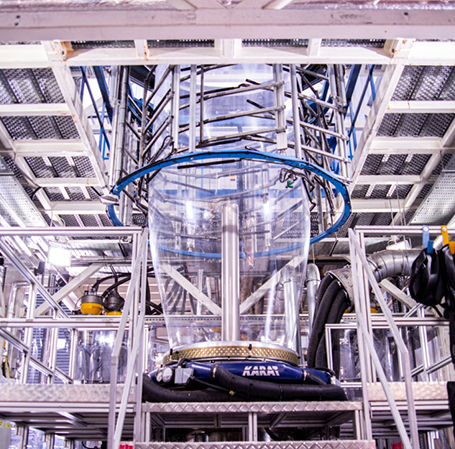

Ineos Olefins & Polymers Europe announced a new application of a new polymer grade to its portfolio of products that comprise of post-consumer recyclates (PCR). The range of recycled polymer grades (Recycl-IN) is growing as Ineos and its partners develop and explore the displacement of virgin polymers with PCR materials. In this latest development, and working closely with the technical team at Coveris in Winsford, Cheshire, a new stretch-hood packaging film, containing a minimum of 30% recycled material, has undergone a series of rigorous testing and trials at Ineos’ manufacturing facility in Grangemouth, Scotland intended for distribution of Ineos’ palletised polymer resin.

These trials have demonstrated that the product integrity and quality is maintained and that the new recycled stretch-hood covering for pallets performs to the same standards as a previous solution made from 100% virgin material. It has been introduced ahead of UK legislation for packaging materials that will require a minimum content of recycled polymers. “This is a significant breakthrough,” says Ineos Polymer Business Manager, Graham MacLennan. “Palletised distribution of goods is increasing and a stretch-hood covering helps prevent waste, damage and loss to products transported in this way. By substituting virgin polymer content with recycled polymers, we are actively working towards our targets to adopt a more circular approach, signalling our clear commitment to using more recycled plastic as a raw material. Our new product, developed in close partnership with Coveris, is a clear demonstration of this. Within Ineos we remain committed to Sustainability, to achieving Net Zero in our operations and bringing solutions to the market that enable others in the supply chain to lower their carbon footprints too.”

This, and other Recycl-IN polymers, are proving that plastics remain a valuable resource, even after initial use. Ineos O&P continues to pursue technological and engineering solutions to increase the recycled content of the materials they produce, and to demonstrate to customers, supply chain partners and to the wider world that their new range of Recycl-IN polymers perform to the high standards that they expect. Mike Richardson, Technical Director, Coveris Winsford said, “Coveris have extensive experience of producing high performance films with significant recycled content. Our collaboration with Ineos has enabled us to develop a new stretch hooding product with 30% PCR content, without increasing gauge or compromising on performance. Supporting our vision of No waste and the wider industry sustainability goals, the new solution offsets the need for virgin plastics whilst maintaining full recyclability, as well as being fully compliant with UK plastics packaging tax. This will allow our customers the benefits of palletised transportation using plastic tertiary packaging without compromising their sustainability and circular economy goals.”

This, and other Recycl-IN polymers, are proving that plastics remain a valuable resource, even after initial use. Ineos O&P continues to pursue technological and engineering solutions to increase the recycled content of the materials they produce, and to demonstrate to customers, supply chain partners and to the wider world that their new range of Recycl-IN polymers perform to the high standards that they expect. Mike Richardson, Technical Director, Coveris Winsford said, “Coveris have extensive experience of producing high performance films with significant recycled content. Our collaboration with Ineos has enabled us to develop a new stretch hooding product with 30% PCR content, without increasing gauge or compromising on performance. Supporting our vision of No waste and the wider industry sustainability goals, the new solution offsets the need for virgin plastics whilst maintaining full recyclability, as well as being fully compliant with UK plastics packaging tax. This will allow our customers the benefits of palletised transportation using plastic tertiary packaging without compromising their sustainability and circular economy goals.”

All rights reserved except agreement written by Emballage Digest or mention of the magazine