Label applicator world premiere at Fachpack for Herma

publié le vendredi 19 juillet 2024

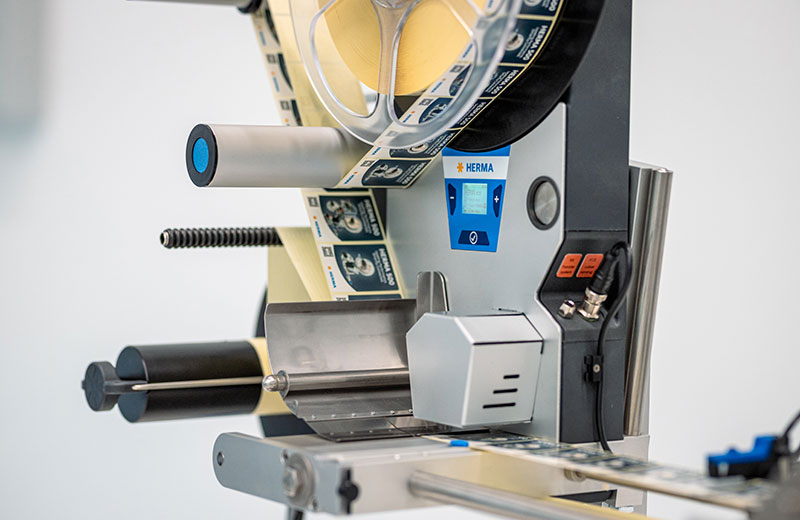

Outstanding cost-effectiveness, high-quality equipment, high manufacturing quality: The Herma eco applicator opens up new options for standard applications. Its integration into a higher-level control system (PLC) is now as extensive and convenient as never before in this Herma performance class. In the Herma online configurator, which is unique in the industry, the new applicator can now be adapted even more comprehensively to individual requirements.

The Herma eco applicator is designed for a diverse range of standard applications and will make its world debut at Fachpack. It combines cost-effectiveness and high quality with a level of engineering and manufacturing quality which is unusually high for this market segment. « This means value retention, durability and investment security, even in the entry-level segment. After all, the Herma eco is produced on the same production line in Filderstadt, Germany, as the high-performance Herma 500 – and therefore carries within it genuine Herma DNA, » emphasizes Martin Kühl, Head of the Labeling Machines division.

Costing the same as the predecessor model Herma basic, the Herma eco boasts a multitude of new features. Integration of the new Herma eco into a packaging system and therefore into a higher-level control system (PLC) is now as extensive and convenient as never before in this Herma performance class. This is made possible by, among other things, a series of additional I/O signals. In conjunction with the system control unit, these signals enable, for example, the automatic power on/power off function, separate starting of the labeling process as well as manual label dispensing, which is an advantage especially when setting up an applicator. Thanks to these signals, end-of-reel checking is now also possible.

Furthermore, the printer and the peel system will in future each have their own connections that can be monitored separately. As a result, it will be possible to use, for example, a printer in combination with a pneumatic transfer unit, which will significantly expand the flexibility and possible applications of the new Herma eco. It is therefore well prepared even for simple pharmaceutical or healthcare systems, not least because it has a master encoder function. This function enables continuous and automatic synchronization with the speed of the conveyor belt. It ensures precision, even at the maximum speed of up to 30 meters per minute for labels with a width of up to 160 millimeters.