Pulsed light sterilization for PP sport cap

publié le lundi 31 mai 2021

Aptar Food + Beverage announced a technical collaboration with Claranor, world leader in Pulsed Light packaging sterilization.

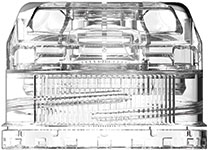

This synergy highlights the benefits of the Fullcap® sterilization solution with the Uno sport cap family in polypropylene (PP) material, specifically adapted for use with functional beverages. Functional beverages containing vitamins and minerals, boosting energy and helping recovery, capped with the most advanced sport closures, require a specific sterilization process that Claranor provides. Claranor’s Fullcap® Pulsed Light sterilization solution goes through the closure, allowing sterilization under the cap, where chemicals cannot go or could be trapped. Claranor equipment is compact, (600mm high), it provides an instant treatment and can be used on speed lines up to 60,000 bph with no chemical nor residue. This solution provides ultimate inner and outer decontamination when applied to Aptar’s Uno PP sport closure family in the translucent material version. It is adapted for high acid aseptic lines. With its non-chemical and non-thermal treatment, it respects the integrity of the packaging and the product inside. Aptar Uno sport cap is a one-piece design, made with mono-material for improved recyclability. Its active hinge provides a comfortable, one-hand opening and closing, and the 28mm version is tethered to the bottle helping to improve the closures’ recyclability rates, and contribute to a more circular economy. Uno is suitable for dry aseptic filling and approved by Claranor Fullcap® sterilization with pulsed light. This closure is available in 1881, 38mm 2S and 3S neck finishes.

Part of 658 issue – May 21. All rights reserved except agreement written by Emballage Digest or mention of the magazine