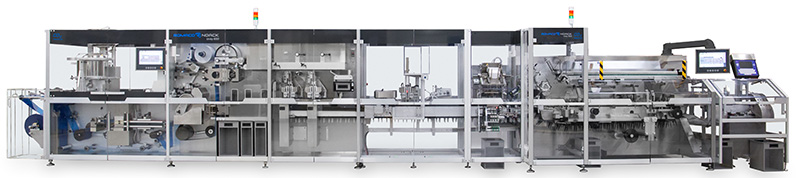

Romaco Noak launches new Unity 600 blister packaging line

publié le vendredi 27 janvier 2023

Romaco Noack has expanded its state-of-the-art Unity family with the Unity 600 blister packaging line. The new technology leads the way in terms of sustainability, process reliability and performance. The heart of this monobloc is the innovative transfer unit, which is not only designed for much higher cycle numbers, but also provides more format flexibility as well as better traceability and energy efficiency.

All in all, the double-lane high speed line – comprised of a blister machine with rotary sealing and a continuous motion cartoner – achieves a maximum output of 600 blisters and 350 cartons per minute. With a maximum foil width of 304 mm, blister packs up to 145 mm long and 90 mm wide can be safely processed.

And for all applications demanding even higher performance, Romaco offers a three-lane version of the Unity 600 with an output of up to 750 blisters per minute.

With the Unity 600, blisters are transferred to the cartoner via an indexing wheel with a downstream stack transfer unit. What’s more, the suction cups of the indexing wheel are only ever active while blisters are being transferred. This means that no air is drawn in erroneously and power consumption is minimized.

This highly automated transfer solution from Romaco Noack additionally allows seamless tracking and tracing of blister packs from the product feeding unit onward.

Features for more sustainability

The Unity 600 can be supplied in a carbon-neutral version on request and meets all the requirements of the pharmaceutical and nutraceuticals industry when it comes to flexibility, quality and performance. The technology is utilized for the primary packaging of solid products such as tablets, capsules and oblongs, and is also suitable for manufacturing sustainable packaging like paper blisters. This GMP compliant line convinces with excellent OEE values – due to short changeover times and very good line clearance.